Laboratoire Léon Brillouin

UMR12 CEA-CNRS, Bât. 563 CEA Saclay

91191 Gif sur Yvette Cedex, France

+33-169085241 llb-sec@cea.fr

Laboratoire Léon Brillouin

UMR12 CEA-CNRS, Bât. 563 CEA Saclay

91191 Gif sur Yvette Cedex, France

+33-169085241 llb-sec@cea.fr

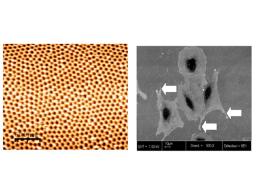

Fig. 1(a) AFM micrograph of the nanostructured oxide layer.Pores form a quasi periodic lattice with defects. (b)Such a surface structure favours the anchoring of osteobast cells as shown in the SEM image. The number and length of protrusions of the cells(arrows) demonstrate the quality of the cell attachment.

During the preparation of ultra flat surfaces of stainless steel for the two above studies of degradation of these materials, we experimented an electrochemical polishing process with a classical bath for obtaining a mirror-like surface. The electrochemical solution consists in perchloric acid in an organic solvent cooled at constant temperature ~ 4°C. Either the current ranging from 0.1 to 0.8A or the voltage varying from 15 to 60V was controlled in the electrochemical cell. AFM images of the electropolished surface showed an unexpected nanostructure. [1] As shown in Fig. 1 (a), the surface is covered by a quasi periodic arrangement of pores with a typical diameter of 80nm and a period of 100-120nm. Large scan images reveal that the arrangement of pores forms grains with grain boundaries and defects as dislocations. Interestingly, this lattice is independent of the grain orientation of the underlying metal. The chemical nature of this overlayer analyzed by X-ray photoemission brings

evidence that the surface layer is formed by chromium and iron oxides. No signal coming from nickel atoms was detected. Changing the electrochemical conditions (temperature, current or voltage) influences the pore diameter and the arrangement period which varies from 50 to 150 nm.

This nanostructured surface appears well suited for improving the quality of osteointegration of stainless steel prosthesis in bones since rough-surfaced implants favour both bone anchoring and biomechanical stability. In collaboration with an INSERM group (Nantes), which studies the interface between bone and metal implants, the anchoring of osteoblast cells onto these nanostructured surfaces of stainless steel was investigated in vitro. The first results shown in Fig.1 (b) have demonstrated that the quality of the cell attachment on these nanostructured surfaces is better than on rough surfaces of stainless steels prepared with standard processes (mechanical abrasion, sanded surfaces,…). [1]

REFERENCES :

[1] F. A. Martin, Ph.D Thesis Paris VI (2005)

•  Les archives de l'IRAMIS et du DRECAM / Archives of DRECAM and IRAMIS › Matériaux, surfaces et nanostructures

Les archives de l'IRAMIS et du DRECAM / Archives of DRECAM and IRAMIS › Matériaux, surfaces et nanostructures

• Laboratory of Physics and Chemistry of Surfaces and Interfaces • Service de Physique et Chimie des Surfaces et des Interfaces

• Laboratory of Oxide Surfaces and Interfaces • Laboratoire des Interfaces et Surfaces d'oxydes (LISO)